IOT in the petrochemical and oil industry is the new revolution

by saulame

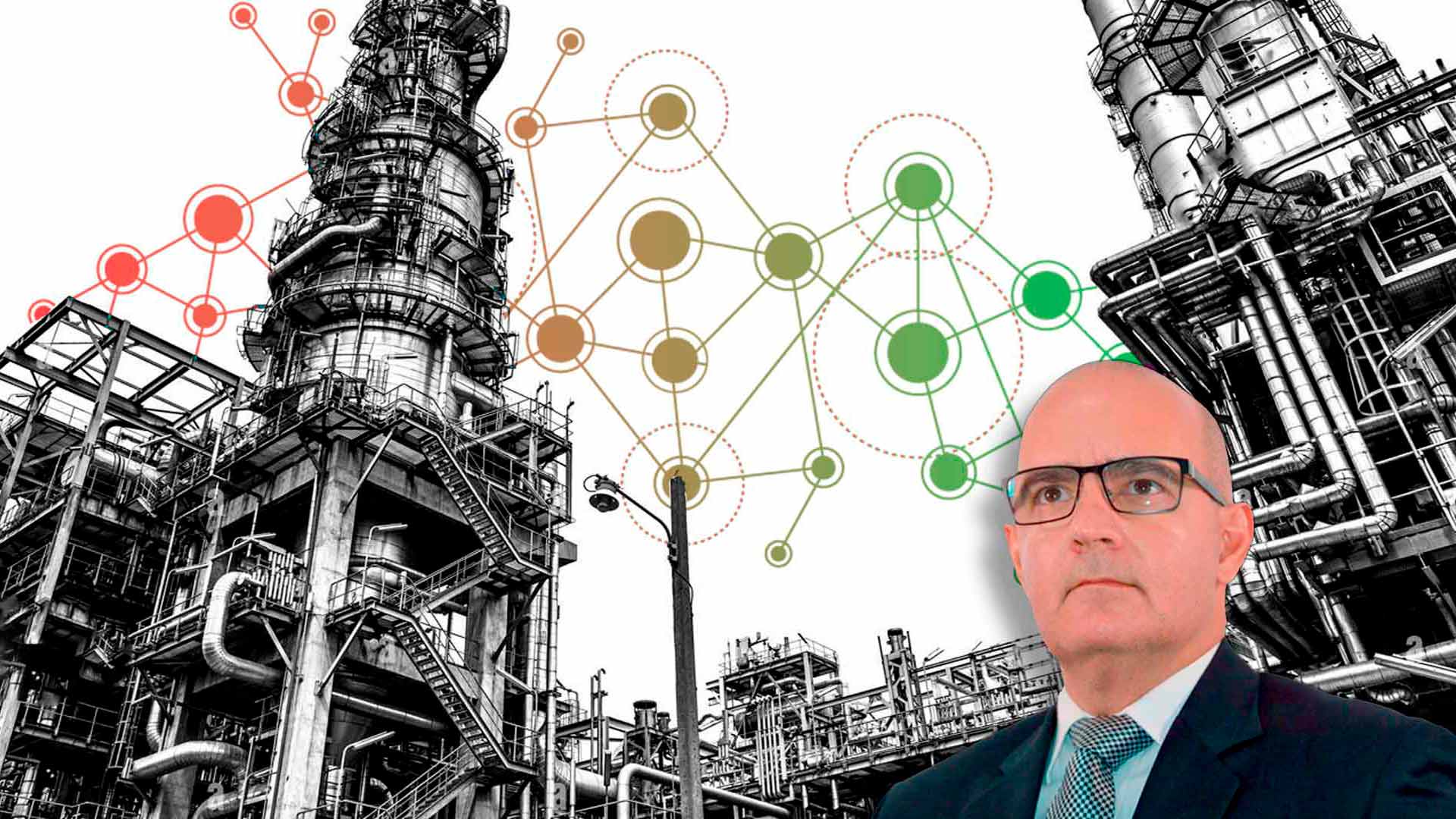

The Internet of Things (IoT) is used in the oil and gas sector to collect, transmit and analyse real-time data to better understand asset processes, improve operational efficiency, reduce energy consumption and increase profitability.

Venezuelan engineer Saul Ameliach Orta, a petrochemicals expert, explains that IoT solutions exist for all major industry segments:

- Upstream operators use it to improve drilling and production management and reduce downtime.

- On the other hand, midstream operators use it to improve fleet management and pipeline and warehouse maintenance.

- Downstream companies use IoT to optimise oil and gas processing, distribution and storage.

Benefits of IoT for the oil and petrochemical industry

Real-time visibility: IoT solutions enable oil and gas companies to monitor and track their fleets and vessels, providing real-time information on equipment performance, safety status, environmental conditions and fleet operations.Predictive maintenance: IoT sensor data from oil and gas assets enables predictive analytics and root cause analysis.

It can also identify potential failure conditions and schedule maintenance in advance to avoid significant downtime. As a result, it ensures that assets are operated efficiently and smoothly.

“This is especially useful for remote assets that are not visible or rely on manual checks,” adds petrochemical expert Saul Ameliach.

The Internet of Things can be used to optimise maintenance schedules and reduce the need for technicians, while ensuring assets are in good working order.

Risk management: IoT solutions can monitor the presence of flammable gases and toxic vapours in the atmosphere and help prevent oil leaks and gas spills. IoT accident prevention features make drilling and production safer.

Increased profitability: These IoT-driven benefits help improve the efficiency of industrial operations.

“Internet of Things solutions enable oil and gas companies to optimise the use of their assets, equipment, manpower and resources. This allows them to increase productivity, reduce costs and ultimately increase profits,” explains Saul Ameliach.

Reducing environmental impact: The oil and gas industry is a major contributor to climate change. It produces more than 40% of global greenhouse gas emissions through its direct operations. Operators can reduce their carbon footprint through leak detection, predictive maintenance and reducing fugitive emissions through IoT.

Similarly, downstream operators can use IoT to increase and improve their energy efficiency.

Regulatory compliance: IoT solutions provide detailed data on plant operations that can be used to improve compliance with regulations and industry standards.

IoT is transforming the industry

The Internet of Things has made downstream, upstream and midstream operations safer, more efficient and smarter by performing advanced functions such as remote pipeline monitoring, well monitoring, reservoir analysis, automation and more.